Tube & Sheet Metal Fabrication

Tube Laser Cutting

Our 4000-watt Amada® rotary laser allows for fast, programmed cuts in tube metal up to 20 feet long, 1.25 inches thick and 8.66 inches in diameter.

Speed: Traditionally, complex work on material of that size would require extensive tooling and production time; however, with our tube laser cutter, our skilled programmers and operators are able to produce complex tube components in a fraction of the time, giving you the short-run flexibility you need.

Shape: Rotary lasers also deliver exceptional capabilities when it comes to material shape. The Amada 4K is capable of cutting round, square, rectangular, c-channel and angle iron—so there’s virtually no tube too tough for our team to tackle.

Tube Laser Cutting Material Capacity

| Shape / Material | Diameter Min / Max | Length Max | Thickness Min / Max |

|---|---|---|---|

| Round / MS | .75 / 8.66 | 240 | .039 / .875 |

| Round / SS, AL | .75 / 8.66 | 240 | .039 / .375 |

| Square / MS | .75 / 6.0 | 240 | .039 / .875 |

| Square / SS, AL | .75 / 6.0 | 240 | .039 / .375 |

| Angle / MS | .75 / 3.54 | 240 | .039 / .875 |

| Angle / SS, AL | .75 / 3.54 | 240 | .039 / .375 |

* MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

All measurements are in inches.

Sheet Metal Laser Cutting

On the cutting edge: custom-cut sheet metal, faster than ever

Sheet metal laser cutting requires speed and precision, and we reflect that by continually investing in equipment that keeps us on the cutting edge of the manufacturing industry. Our arsenal includes a strategic array of Amada lasers to maximize our capabilities, production efficiency and delivery.

Speed: When turnaround time is the most important factor, we employ the 9,000-watt Amada 3015 AJZ. This fiber laser can cut 4 to 7 times faster than CO2 models, up to 1,800 inches per minute. That means you can get finished products delivered faster than ever before.

Volume: For high-volume production runs, we’ve integrated the 9K laser inline with a 4,000-watt Amada and a 15-shelf automated tower system. The result is a production line that allows for continuous operation, running around the clock to satisfy your most demanding needs. This automated system also excels in small runs and prototype support.

Material Spec: The 9K/4K system can cut material up to 1 inch thick, for sheet sizes up to 60 inches x 120 inches. If your project requires a larger sheet size, that’s where our 6,000-watt Amada sheet metal laser comes in. This equipment can handle material up to 80 inches wide x 160 inches in length.

By using sheet metal laser cutting rather than traditional machining, we limit tooling, which results in faster time to production and cost savings for you.

Sheet Metal Laser Cutting Material Capacity

| Material | Width Max | Length Max | Thickness Min / Max |

|---|---|---|---|

| MS | 80 | 160 | .039 / 1.25 |

| SS, AL | 80 | 160 | .039 / 1.0 |

* MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

All measurements are in inches.

Metal Rolling

Barrels and other cylindrical or conical products are made possible by our WDM Workhorse 4-roll pinch roller. In combination with other capabilities, our metal rolling equipment allows us to create 3-dimensional sheet metal products.

Material Capacity

| Material | Width Max | Conical Min Diameter | Thickness Max |

|---|---|---|---|

| MS, SS, AL | 72 | 7.25 | .3125 |

* MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

All measurements are in inches.

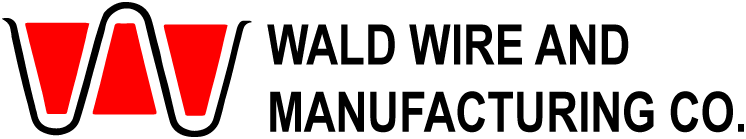

Sheet Metal Forming

The heart and soul of any sheet metal fabrication shop is its press brake. Our 243-ton, 230-ton and 175-ton CNC press brakes give us the capacity to form a wide range of complex bends in a variety of materials and thicknesses. With a keen understanding of the relationship between material, thickness and radius, our engineers and operators will ensure that your bending spec is met with unbending results.

Material Capacity

| Material | Width Max | Stroke Max |

|---|---|---|

| MS, SS, AL | 168 | 22 |

* MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

All measurements are in inches.

Sheet Metal Punching

When you need 3-dimensional features, such as louvers or embossing, our 55-ton, Amada Vipros 568, CNC 62-station turret punch press can tackle just about any project. Forming repetitive, simple cuts is often more efficient with sheet metal punching rather than laser cutting. Whatever you project needs, we have three-punch presses waiting to serve you.

Material Capacity

| Material | Length | Width |

|---|---|---|

| MS, SS, AL | 157 | 60 |

* MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

All measurements are in inches.

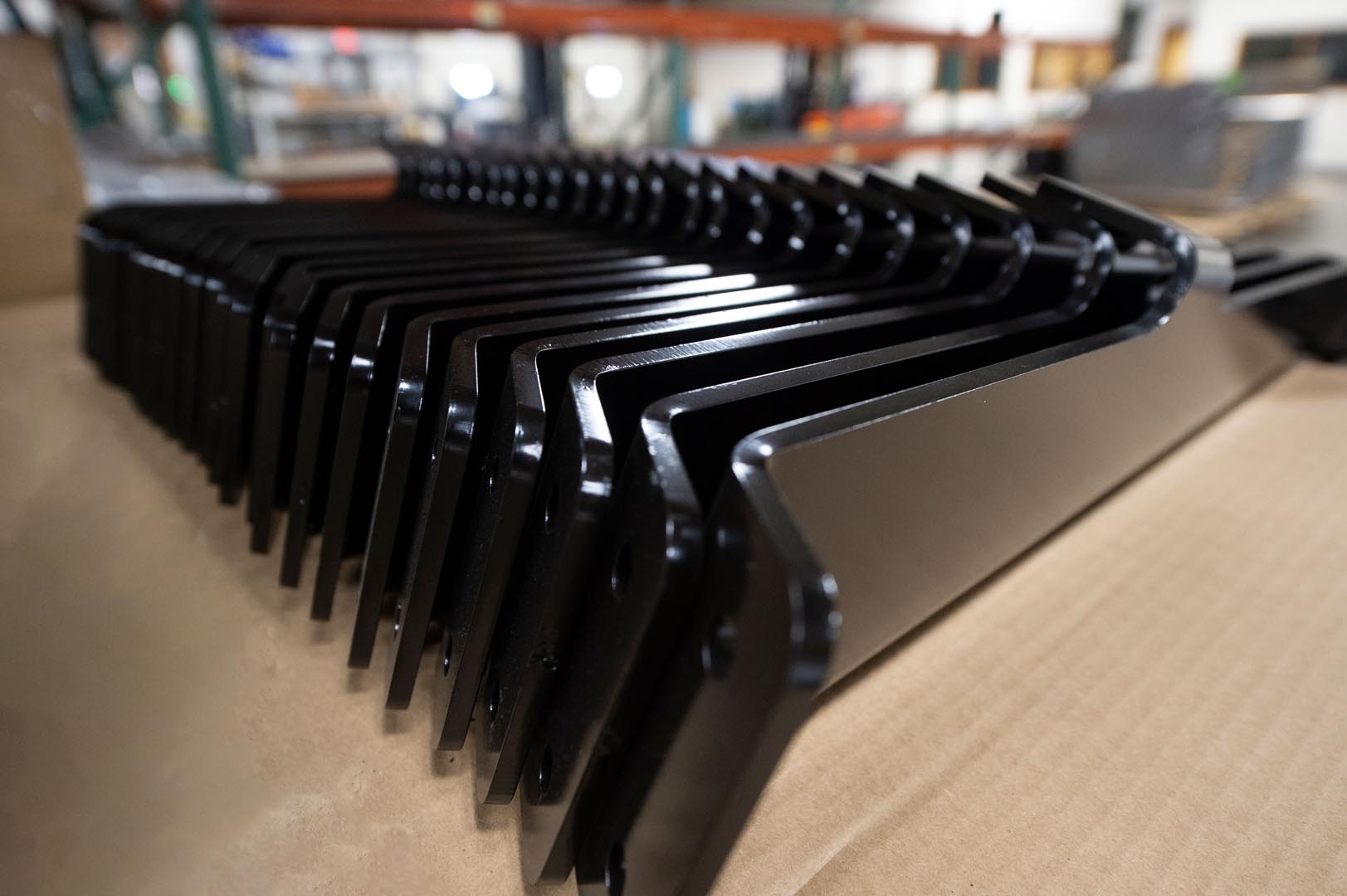

Secondary Operations

In addition to the sheet metal cutting capabilities already mentioned, we have CNC saws and mills ready to perform a variety of secondary operations when needed. No matter the complexity of your order, Wald Wire has the experience and equipment to handle your sheet metal fabrication project.

In-House Toolmaking

To provide the speed and flexibility you require, we have in-house toolmaking capabilities that allow us to deliver in days what some shops would deliver in weeks. Especially significant for short-run production, our in-house toolmaking capabilities give us the flexibility to handle any size project.

Your Flexible Manufacturing Partner

When you’re looking for a sheet metal fabrication shop, trust the experience Wald Wire will bring to your application. Our Wisconsin sheet metal shop has the equipment and expertise to deliver the right product at the right time, along with the processes to meet your flexible supply chain needs.